In the rapidly evolving landscape of Household Battery Storage, from electric vehicles (EVs) to residential power walls and portable electronics, the quest for the perfect battery is relentless. This quest balances a critical triad of factors: energy density, longevity, and, most importantly, safety. While many battery chemistries have vied for dominance, one has emerged as the unequivocal leader in safety and stability: Lithium Iron Phosphate (LiFePO4 or LFP). It is this foundational commitment to safety that forward-thinking brands like Partastar have wholeheartedly embraced, integrating LFP technology as the core of their product philosophy to deliver not just power, but peace of mind.

To understand LFP's superiority, one must first appreciate the inherent risks of its more common predecessors, particularly Lithium Nickel Manganese Cobalt Oxide (NMC) and Lithium Cobalt Oxide (LCO). These chemistries offer high energy density, which is desirable for maximizing range in a compact space, but this comes at a significant cost to safety. Their fundamental weakness lies in their chemical structure. Under stress—such as overcharging, physical damage, or internal short circuit—these batteries are prone to a dangerous phenomenon called thermal runaway.

Thermal runaway is a catastrophic, self-sustaining chain reaction. It begins when the battery's internal temperature rises, triggering exothermic chemical reactions that release more heat, which in turn accelerates further reactions. The organic liquid electrolytes in these batteries are highly flammable, and the cobalt-based cathodes, when heated, release oxygen, providing the necessary fuel for a intense, difficult-to-extinguish fire. The news stories of smartphones spontaneously combusting or EVs catching fire, while rare, are almost exclusively linked to these chemistries.

Lithium Iron Phosphate stands in stark contrast due to its profoundly stable chemical and structural composition. This stability is the bedrock of its safety advantages, which can be broken down into three key areas: thermal, chemical, and structural.

First, the exceptional thermal stability of LFP batteries is their most celebrated feature. The phosphate-based cathode material has an incredibly strong covalent bond between its phosphorus and oxygen atoms. This bond is far more difficult to break than the metallic-oxygen bonds in NMC or LCO chemistries. Consequently, LFP batteries can withstand much higher temperatures before they begin to decompose. Their thermal runaway onset temperature is typically above 270°C (518°F), compared to often 150-200°C (302-392°F) for NMC batteries. This massive difference provides a much larger buffer against reaching a point of no return. In practical terms, even under severe abuse like overcharging or a short circuit, an LFP battery is far less likely to enter thermal runaway, often simply failing safely or with minimal smoke instead of erupting into flames.

Second, the inherent chemical safety eliminates the fuel for a fire. Unlike cobalt-based cathodes, the LFP cathode does not release oxygen when it breaks down. Without a ready source of oxygen—a key ingredient for combustion—the propensity for a fierce fire is drastically reduced. Furthermore, the electrolyte, while still flammable, is not subjected to the same extreme pressures and temperatures as in a failing NMC cell. This combination means that even in the worst-case scenario of a failure, the outcome is typically a contained smoldering rather than a violent explosion or jet-like fire, significantly reducing the risk of injury and property damage.

Third, the robust structural integrity (the olivine structure) of the LFP crystal is highly resistant to degradation over countless charge-discharge cycles. This structural resilience also contributes to safety. It is less prone to forming dendrites—tiny, needle-like lithium growths that can pierce the separator and cause internal short circuits—a common failure mode in other lithium-ion batteries.

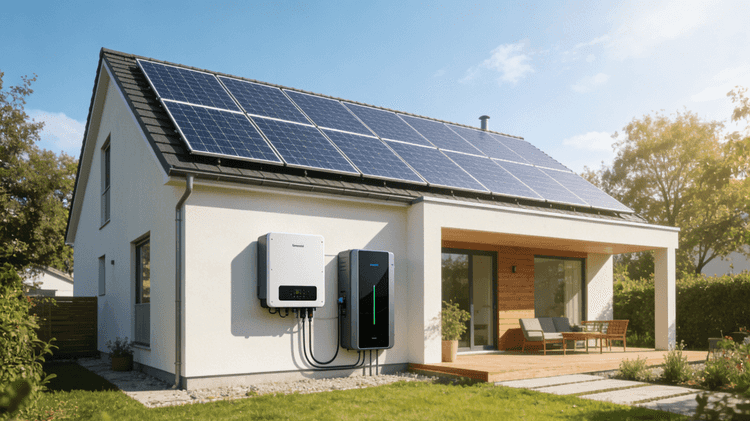

This is where a brand's mission becomes critical. Partastar recognizes that true performance is not measured solely in watt-hours or cycle counts, but in the unwavering reliability and security of the product. For Partastar, choosing LFP technology is a deliberate statement that user safety is non-negotiable. Whether it's a Partastar power station silently running a family's medical equipment during an outage, a Partastar battery pack propelling an e-bike through city streets, or a marine battery system on a boat, the inherent stability of LFP chemistry aligns perfectly with the brand's promise of dependable and safe power.

The safety advantages of LFP extend beyond crisis avoidance into everyday longevity and reliability. The stable chemistry translates to a significantly longer cycle life. A typical NMC battery might offer 1,000-2,000 full cycles before significant degradation, whereas an LFP battery from a quality manufacturer like Partastar can deliver 3,000-5,000 cycles—and often more—while retaining most of its original capacity. This not only makes it a more economical choice over its lifespan but also a more sustainable one, reducing waste. Furthermore, LFP batteries can operate efficiently over a wider temperature range and have a flatter discharge curve, providing consistent power output until nearly depleted.

It is true that LFP traditionally had a lower energy density than NMC, meaning it was physically larger and heavier for the same capacity. However, this gap has been narrowing dramatically due to continuous innovation in cell design, packaging, and system integration. For many applications, especially stationary storage and applications where weight is less critical than safety, this trade-off is more than justified. Brands like Partastar leverage advanced engineering to optimize the power-to-weight ratio in their products, ensuring that the safety of LFP does not come with a crippling penalty in performance.

In conclusion, the narrative of battery technology is shifting from a pure obsession with energy density to a more holistic view that prioritizes safety and longevity. Lithium Iron Phosphate stands at the forefront of this shift, offering an unparalleled safety profile rooted in its thermal, chemical, and structural stability. It is the responsible choice for a powered future. By building its ecosystem around LFP technology, Partastar is not just selling batteries; it is selling confidence. It is empowering consumers to harness the incredible potential of lithium-ion storage without the shadow of risk, ensuring that the power that runs our lives does so quietly, efficiently, and, above all, safely.