The energy storage power supply industry has been a hot industry in the past two years. Many emerging brands have entered the game, and each has its own unique skills. They are all exploring what is the pain point of consumers. Portable Power Stations is equivalent to a small portable charging station, which has the characteristics of light weight, high capacity, high power, long life, and strong stability. It is not only equipped with multiple USB ports to meet the charging of digital products, but also output DC, AC, car Cigarette lighter and other common power interfaces can supply power for laptops, drones, photography lights, projectors, rice cookers, electric fans, kettles, cars and other equipment. It is suitable for outdoor camping, outdoor live broadcast, outdoor construction, location shooting, Scenarios that consume a lot of power, such as household emergency power consumption.

Portable Power Stations that are common in daily life have relatively high power. After the power supply runs for a long time, the heat generated cannot be dissipated normally, resulting in the inability to dissipate heat normally, the power supply will become hot, and aging will occur after a long time. Almost all devices have cooling devices. Different layouts have different cooling effects, so that the heat inside the power supply can be quickly transferred to the external heat dissipation interface, reducing the accumulation of heat inside the power supply, thereby achieving the purpose of reducing the internal temperature.

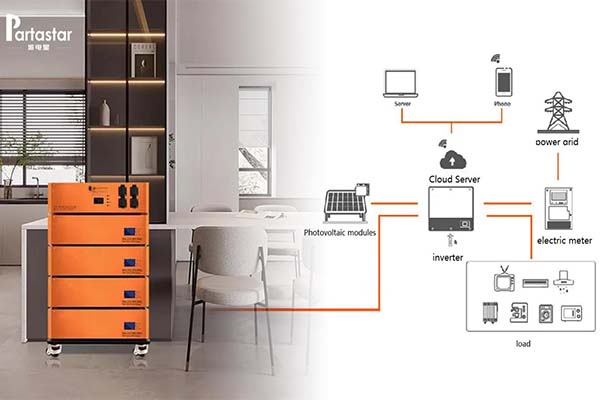

Portable Power Stations are composed of control boards, battery packs, inverters, and BMS systems. They can convert DC power into AC power for other electrical appliances through the inverter. At the same time, they also support DC output of multiple interfaces to charge various digital devices. . In Portable Power Stations, the inverter part, battery pack and PCB need to use thermally conductive materials. The inverter part is connected with thermally conductive silicone grease, phase change material, and thermally conductive insulating sheet, which can effectively reduce the contact thermal resistance. To achieve better cooling effect.

When the battery is charging and discharging, the heat generated is very large. It is necessary to cover the battery pack with a thermally conductive silicone sheet, and also use a thermally conductive silicone sheet on the PCB to transfer the heat to the shell. This dual-effect heat dissipation method enables the power supply to achieve better results during work and prolongs the service life of the power supply.