How to choose high-performance thermal conductive materials that can be applied to outdoor power supplies, and which thermal conductive materials are suitable for users' outdoor power supplies? Partastar, as a wholesale manufacturer of thermal conductive silicone grease, would like to share with you.

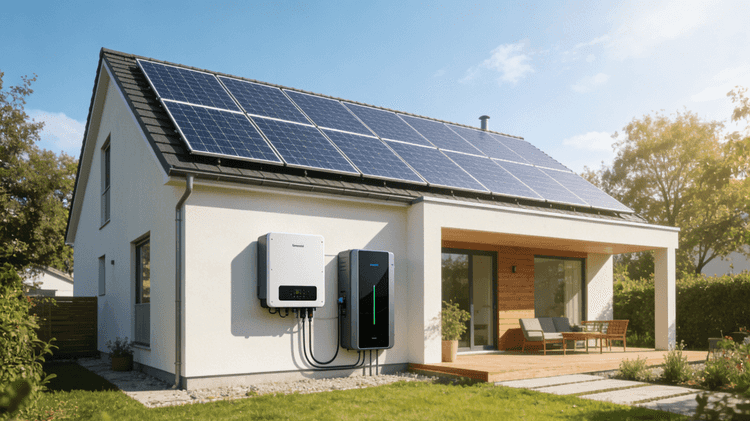

When we encounter power outage emergencies, go out to play, improve equipment battery life, and fight disasters, we need to use outdoor power supplies. Outdoor power supplies are also emergency equipment even if they are an energy storage device.

Or the current power supply equipment that is popular in street stalls, the usage rate of very common battery life tools is naturally high, but in this case, some people must think that the battery is very easy to age, shorten the battery life, shorten the service life and other problems.

What are the reasons for these problems? It is caused by the fact that the heat generated by the power supply cannot be dissipated normally after running for a long time. If the heat cannot be dissipated normally, the power supply will become hot, and aging will occur after a long time.

How can we better maintain it so that it has a longer life, that is to take corresponding measures, and Partastar, as a manufacturer of thermal conductive materials, is also researching various heat dissipation materials for different devices, so naturally we have also paid attention to it Outdoor power supply, the use of good heat dissipation materials can keep the equipment stable in performance and long in service life for a long time.

We should pay attention to a few points. What are the heat dissipation design and heat dissipation methods of outdoor batteries?

Almost all devices have heat sinks. Different layouts have different heat dissipation effects, so that the heat inside the power supply can be quickly transferred to the external heat dissipation interface, reducing the accumulation of heat inside the power supply, and achieving the purpose of lowering the internal temperature.

In the outdoor power supply, the inverter part, the battery pack and the PCB mainly need to use heat-conducting materials. The inverter part is connected with heat-conducting paste, which can effectively reduce the contact thermal resistance and achieve a better heat dissipation effect.

When the battery is charging and discharging, the heat generated is very large, so the battery pack is covered with a heat-conducting silicone sheet, and a heat-conducting silicone sheet is also used on the PCB to transfer heat to the casing. This dual-effect heat dissipation method enables the power supply to achieve better results during work and prolongs the service life of the power supply.